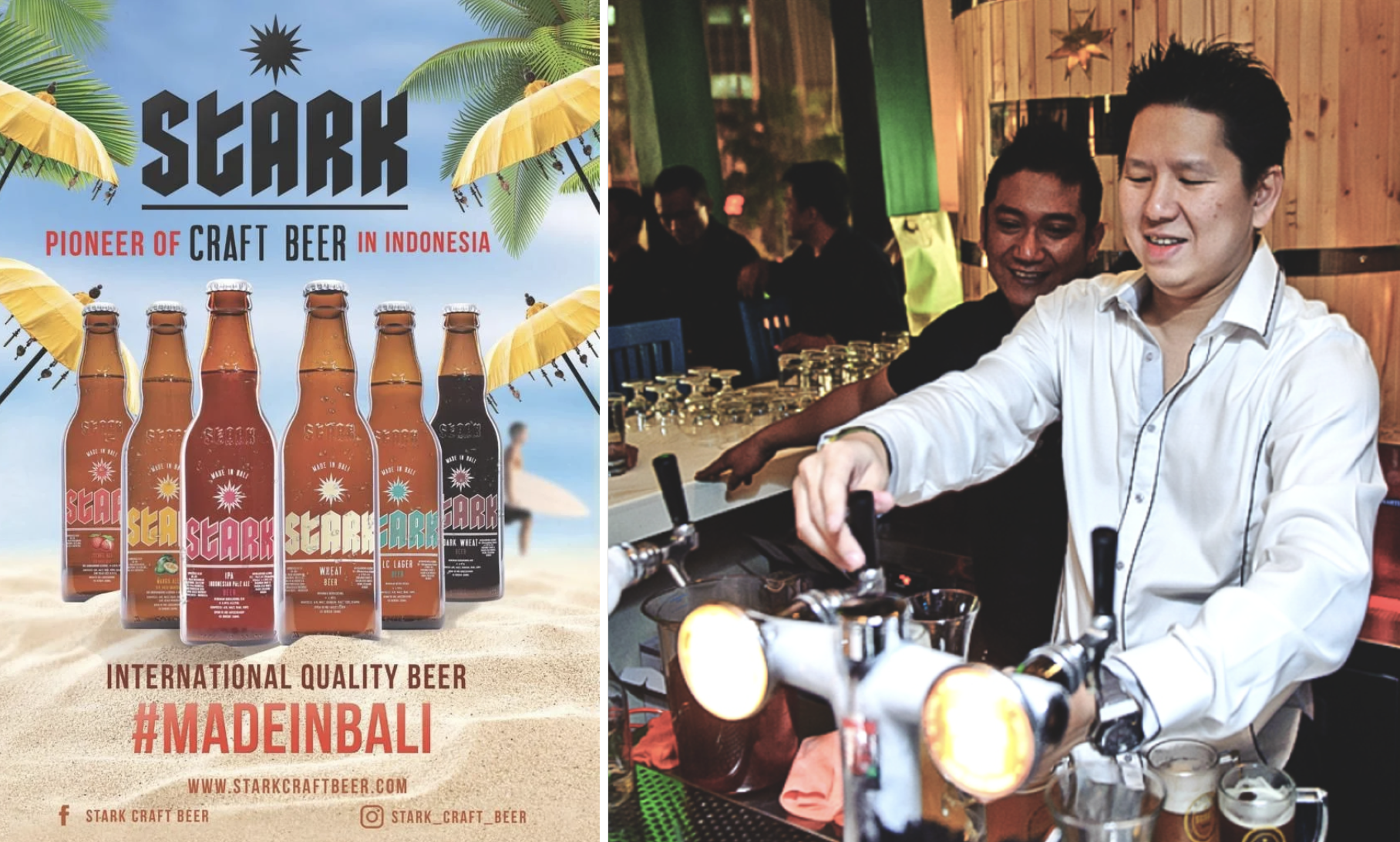

Interview with Bona Budhisurya from Kaja Craft Spirit & Stark Craft Beer!

How did you start your distilling journey?

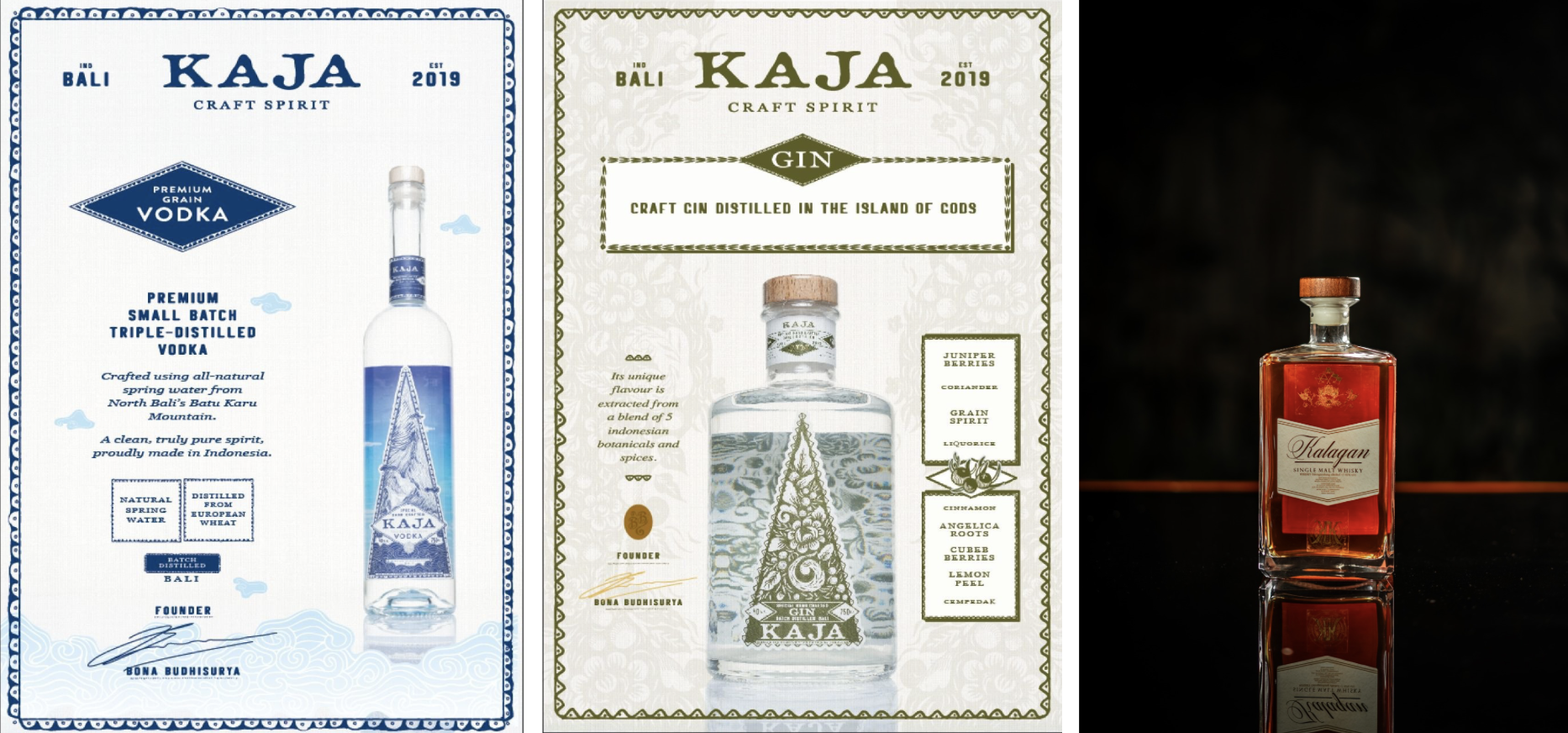

I actually started in 2010, when I went to Belgium and also Australia to visit craft breweries. There was nothing like that available in Indonesia, so I started my journey with a brewery. In 2010 I got my license and building, bought the land, built the brewery and everything. In July, 2011, we started selling. That was only beer, craft beer. We are the pioneers of craft breweries in Indonesia. Back then my license was only for up to 5% alcohol, but in 2017 I got another license for 5-20% and also 20% and above. Therefore, I expanded my factory production from the brewery and built a distillery next door. Afterwards I went to iStill to learn how to distill. I bought the 2000 liter iStilll, installed it there and we started the craft spirit production. I began with gin and vodka and introduced the Kaja product line. Kaja in Balinese means North. We chose this, because our location is also in the North of Bali.

In Hungarian it is slang for food haha, I like it though! Represents the roots of your production. Can you tell some more about your spirits?

Our vodka is produced 100% with malt (wheat) and the taste is very similar to Grey Goose. Our gin is a premium and unique gin. We are the only ones who can produce from malt, because we have a brewery. Other companies in Indonesia just buy molasses from local producers. They will get to 96% ABV and then dilute it with water, put essence in it, like juniper berry essence in the case of a gin, which is essentially flavoring. We don't do that. We buy our juniper berries and some other stuff from the UK to use fresh ingredients. I actually got the contact from Odin hahaha. Later on we started producing whiskey as well, where we are using single malt, 100% barley and we buy yeast from Fermentis, that is specifically for Scotch whiskey. We do the 5 days of fast aging, by putting some wood chips in it, then we put it in a barrel. I imported 40 barrels of 350 liters from Bordeaux, from Limousin Forest, and from Navarre Tonnellerie. Already after one year of barrel aging we get very good results, because in Bali it's all hot. We don't have any winter, so the maturation process is faster. I sent a bottle of this whiskey to you as well, it is called Kalagan.

I will make sure to try it! You have quite a few impressive products. So, before even starting distilling, you already had a clear vision to go with iStill? Haven’t tried other manufacturers’ equipment?

When we wanted to buy distilling equipment we looked at traditional stills and also at iStill to compare them. We chose iStill because of the different design and different process. Everything is computerized and we can program it, reprogram it according to what we want. More lingering in the heads or longer after taste for the tail, it is all possible with a few button presses, so I decided to go with it because it is more manageable in a way.

That’s for sure. Where did you hear about iStill? How did you find the company?

My partner sent it to me. He told me that there's this new distilling equipment from Holland and I have to check it out, so I did that and compared it to the traditional distilling equipment. This was explained in more detail, so it made sense to me. It is a square shaped distilling equipment, and because of that, it's actually mixed better. Everything makes sense, because my background is mechanical engineering. I decided to buy, then I went there to meet Odin and took the class, so I understand everything behind it. Also we did ask someone to come to Bali and William came over. He trained our people, our team, how to use this equipment. After that, I also explained in Bahasa Indonesian so they understand more. Then we just started producing continuously and improving everything.

How big is your team, the organization? How many people are working with you?

We have about 100 plus in our production, because some of the bottling process is still manual. We have different bottle shapes and sizes, so we still use some manual labour, because Indonesian labour is not expensive, so it just makes sense. Also, if we would only have machinery, we could not hire that many people, and it is great to provide an opportunity for locals. We can hire everyone in the area where we have the production distilling and brewery, so we have a big team and everyone can benefit from the factory.

That is indeed a win-win situation for both you and the employees. How many liters are you producing per month or per year? What's the output that you are creating both from the beer side and the spirit side?

Actually, to be honest, I have never calculated it, because it always depends on the demand.

How many bottles are you selling? You may know that. An average estimate is enough.

Our product variety is very big and our sales per month is about $500.000. I can only tell you the number, the monthly sales, because in what distribution the beer and spirits get sold depends on the demand each month. My job is actually more on the craft spirit side. I want to push and tell the world that in Bali we have great products, quality craft spirits. We are using a fruit that's called cempedak for our Kaja Gin. It's like a jackfruit, just smaller and has more of a unique flavor. You cannot find it in other parts of the world, only in Indonesia or in Thailand. Another unique spirit that we need to push to the world is Arak Bali. That is actually a Balinese traditional spirit that has been there for ages, but we fine-tune and redistill it. Normally it is only distilled one time. We do three time distillation, so it is smoother and not too strong of the flavor, so it's easier to accept by the tourists. We are available at the airport duty free shop and that one is selling quite good.

The duty free shop is definitely a good place to sell something unique like that. Do you also sell online? Where can anyone interested find you products if they want to try?

That's a problem in Indonesia unfortunately. You cannot send your product by post or courier if it is alcoholic. The demand is big, but unfortunately, according to Indonesian law, anything that we ship overseas has to be in one container together with other alcoholic products, so I cannot send just two or three bottles overseas. It would not pass customs. I need to find importers and distributors to make our product available in other parts of the world.

Yeah that’s a tough situation. I hope you can find some good platforms, because I can imagine that people from all over the world would be interested in trying your products. They are quite unique. I want to ask you a bit about iStill now. Do you have any feedback for us after using the machines and system for so long? Do you have anything that you want us to improve in the future?

We don’t use the basic recipes that are in the system, so I cannot give feedback about those, because we only use our own recipes. For what I've been using it, I have not encountered any problem at all. If I have any questions I just give a call to you guys and get it sorted out, but never anything major. The only problem will be that I need to buy a bigger one soon, the 5000 liter one hahaha.

We are looking forward to that!

Are there any crazy new inventions Odin is working on right now?

Yeah, he is always busy and coming up with ideas. Most of it I can’t talk about, but we just introduced a coffee roaster to the market, which can also be used in beer production for making caramellised malts for example. We are also looking into new ways to meet our customers’ needs with iStill. That is one of the reasons I am doing these interviews to get some feedback from people that actually use our machines and see if there is room for improvement. So far everyone is positive, which is good to hear.

Yes, I can understand that. I bought the Mini still as well for experimenting and it works just as fine as the big one.

What achievements are you proud of in your journey and what are you looking forward to accomplishing in the near future?

Well, we just became listed last year in October, so our company is not private anymore. Now you can buy the shares or stocks from the company. This was a big step. For what's next, I get a lot of questions about what my dream is and what I want to achieve that is possible in imagination. Since I love tequila so much, my dream is to have a tequila plantation in Bali and start producing agave spirit. We cannot call it tequila of course, because it's not that part of the world. When I go around here in Bali, I see agave plants sometimes just in the wild. In some areas there are a lot of agave. Maybe it is not blue agave and it is not agave weberi, but it is agave espadin, which is commonly used for mezcal. I started to move all the plants that I find in Bali to my land. I built a traditional oven and everything, then we used the sugar cane machine to squeeze the juice to produce the spirit. The first time it was not that good, then in the second trial we improved it and it turned out to be really good, so the next big thing for us is gonna be agave spirit. Last month I went to the plantation and took a picture. The plants are already as tall as me.

The climate is really good for them in Bali then. That's great news.

Yeah, it even grows faster in a way. I went to the US and I took my team to learn more about agave spirit. The speaker was the master distiller from Tapatio Tequila. Very good quality tequila. I gave our agave spirit to him and asked for his opinion. He tasted it and said wow this is very good, how did you process it, what did you do? I said, well this is actually from roadside agave, so yeah we are trying to produce a good quality spirit, craft spirit with the iStill, which helps a lot of course. Now I have the plantation ready and maybe already this year, we're going to add this new spirit to our portfolio.

That sounds great! You are welcome to send us a bottle of course. Anything else that you would like to highlight at the end of the interview?

Well, we have a premium liqueur product line, called Nord. We don’t start from scratch, we buy the molasses, distill it 6 times until it is clean and add essences that are purely made with fruits and not chemicals. These liqueurs can be used in bars to mix them for cocktails. We have many flavours, like mango, coconut, etc. and we hope that they will get the deserved recognition soon, because they are really high quality!