Machine Maintenance Management!

Your responsibilities increase

As an employer you have the obligation to create a safe working environment for your employees. If your staff works with machines, these machines need to be in good working order. How do you ensure that they are in good working order? Well, because you can inform the authorities that you have diligently followed the maintenance schedule provided by the manufacturer of the specific machine your staff works with.

iStills do not break down

As we designed iStills to not break down, it felt weird to force a maintenance schedule upon you. But now our hand is forced by legislators around the world: as a machine manufacturer we simply need to provide a maintenance schedule ... and you'll have to follow it to avoid liabilities.

iStill Maintenance Schedules

To help you in your duty to inform the legislator about your company maintaining a safe working environment for its employees, we are designing iStill Maintenance Schedules. These maintenance schedules will inform you about the items that need to be replaced and when that replacement needs to take place. Think about new seals and agitator engine oil on a yearly basis. Not as a reaction to something breaking. Not even as a preventative maintenance measure. No, we'll simply prescribe strict maintenance schedules. Why? Because that's what gives you the best argument in convincing the legislator that you upheld the highest standards. Allow me to explain ...

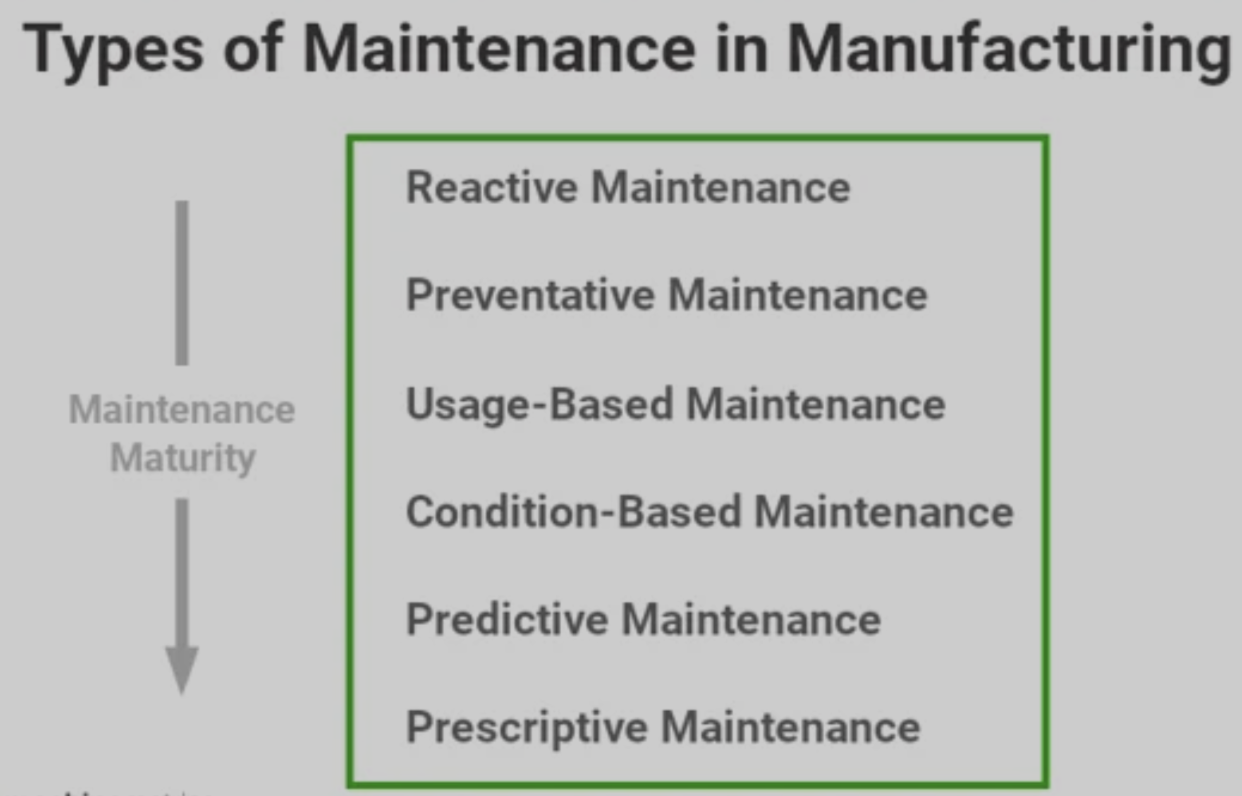

An Introduction to Maintenance Maturity

The legislator distinguishes between six different forms of maintenance. Rock-bottom sits reactive maintenance. Like in something breaks and you need to fix it. Just above reactive maintenance sits preventative maintenance, where you make sure a machine gets maintenance to make sure it does not break down. The third level of maintenance, considered to be of more maturity than the two previous ones, is usage-based maintenance. This takes into consideration how many hours the machine is used. Makes sense, right? The more you use a machine, the more maintenance it requires to keep it in a safe working condition. But there is more ...

Condition-based maintenance is - again - considered of higher quality than usage-based, preventative, or reactive maintenance. As the conditions in which a machine operates influence its longevity and potentially its safety, that makes sense. Predictive maintenance is where the machine can evaluate its own condition and indicate that maintenance will be needed. This is the second best way to manage machine maintenance. The best way? Prescriptive maintenance, where the manufacturer of the machine prescribes what you need to do, maintenance wise.

iStill Maintenance Maturity

We want the best for our customers, so we choose prescriptive maintenance, which has the highest degree of maturity. This decision is also in line with how much we value both quality as well as our reputation, and your prosperity: iStill is the Rolls-Royce of distillery manufacturers.

The future of maintenance ... and how we help out

As per 2025 you can receive an online maintenance schedule for your iStill. In order to fulfill your safety obligations, you can purchase the maintenance parts with us. If you have iStill Data Logging, we can check your machine online and confirm that the right parts have been ordered, that you declared the maintenance to be executed, and that the data logging shows no alarms. VPN & Support is a prerequisite for us to be able to upload your maintenance schedules on your iStill. The invoice for those services will be emailed to you on January 1st 2025, as we informed you about earlier.

Warning

If you have other equipment - mashers, pumps, fermenters - or other stills next to your iStill, please reach out to its manufacturers and ask for their prescriptive maintenance schedules, so that you will not find yourself liable or uninsured, in your distillery.

Prescriptive maintenance has the highest maturity ...

www.iStill.com