Odin on Rolls-Royces and Agitator Engines!

Introduction

As a still designer and manufacturer, we take pride in our craft. iStills do not just introduce new and innovative technology to the craft distilling industry, but also excel in robustness and longevity. Our distilling solutions deliver on all counts. This is the result of a meticulous focus on quality, that has earned iStill the nickname of being the Rolls-Royce of Stills, a characterization we are proud of.

Today, and in some future posts, I want to introduce you to quality still design. I'll give examples of design choices made by us or others, and how these choices affect you and your still, one topic at a time. Today, I'll focus on agitators. Not agitation or mixing, which deserves its own topic, but on agitator engines specifically: that which makes your mixer go round!

Goal

The goal of the agitator is to actively mix the boiler contents of your still. The mixing helps create a more even heat distribution and prevents scorching. As such, and depending on what you produce and how you produce, the agitator can be quite essential. Imagine trying to distill a grappa from fermented pomace without agitator, and you can easily imagine the disastrous outcome: the thick boiler content gets heated in an uneven way, resulting in scorched grape-skins, and an undrinkable spirit.

For your still to work, it probably needs an agitator. And for your agitator system to work, it is essential that the agitator engine works as it should. If the engine breaks, you might not be able to produce spirits. A loss of income is the direct result, and a loss of reputation might follow, when you cannot fulfill your contractual obligations.

Reasons enough to put some thinking into agitator engine design and placement? I think so, but others seem to disagree. Let's dive in deeper and see what's wrong with most current agitator engine designs.

The issue

Most still manufacturers have no clue about how to design a mixing system in general or the agitator engine specifically. As a result, their stills get equipped with suboptimal solutions, that result in the compromised longevity of an essential part of your still. We see distilleries that need to change their agitator engines every second year. And of course they always break when you need 'm most!

What are the design flaws that we see other still manufacturers struggle with? Why do their agitator engines have a longevity of only two years, instead of the 10 year lifespan we offer? They make three main mistakes:

- Engine power;

- Engine placement;

- Engine-to-boiler connection.

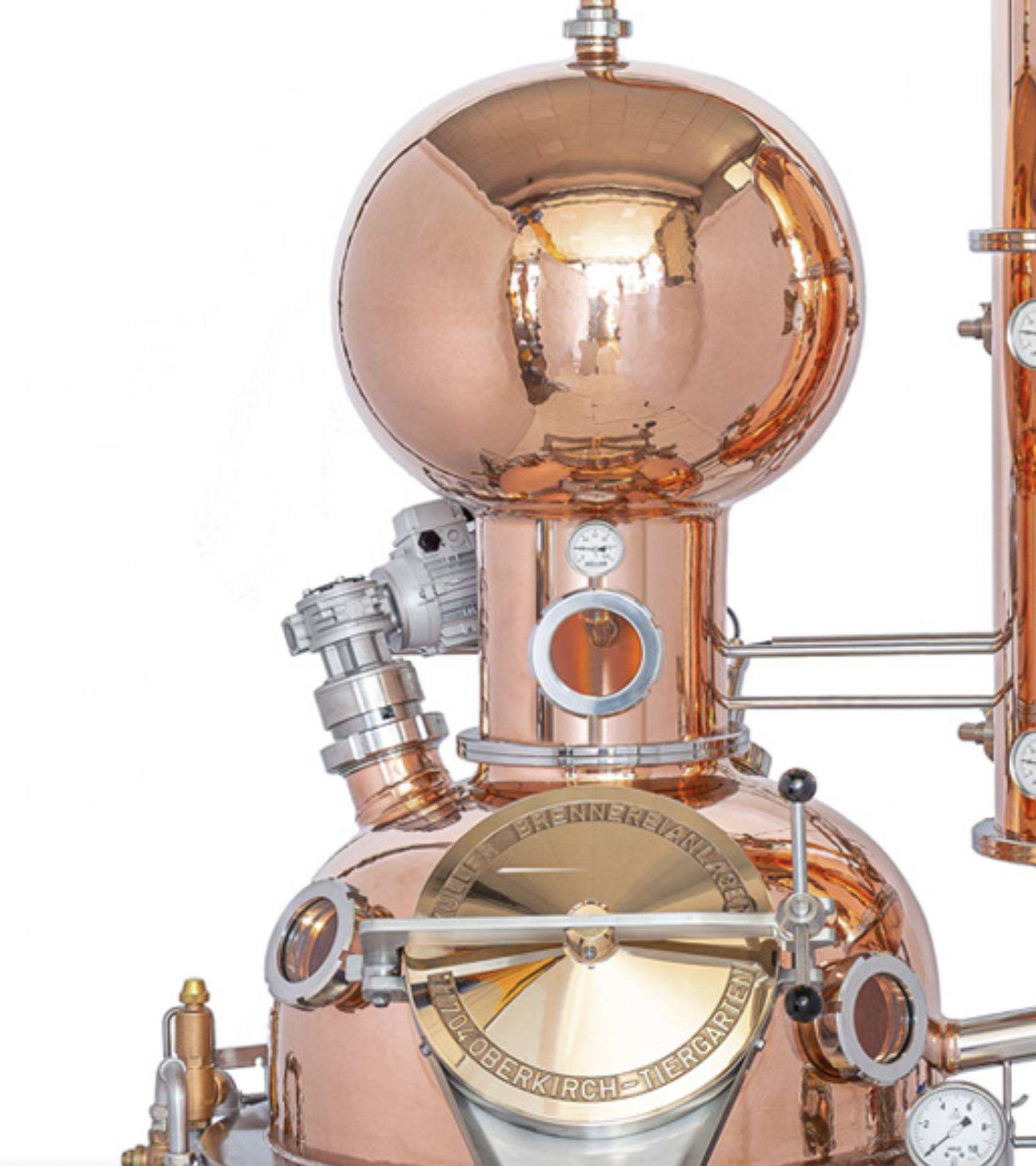

Traditional still with small, ill-placed, and poorly connected agitator engine ...

Agitator engine power

Traditional still manufacturers call agitator engine suppliers, inform them about boiler size, and ask for their cheapest offering. As a result, they get a minimum requirement agitator engine. One that's just strong enough for the job.

The result of this choice is a limited lifespan agitator engine. Even though, theoretically, the chosen engine should still last five to seven years, in practice they never do. Here's why:

Agitator engine placement

Traditional still manufacturers often choose an off-set, horizontal engine design. This asks for an additional planetary gear system that makes the complete mixing set-up more complex. The planetary gear system, a power transfer point, becomes a stress point: a part that is subject to friction and accelerated wear. The off-set position creates torque that further amplifies and accelerates damage build-up.

A secondary issue with a "horizontally" mounted agitator engine is the bigger surface area it presents to the boiler. As the boiler heats up and radiates out heat, mostly upwards, the hot air above the boiler hampers a proper working of the oil cooling fins on the actual agitator engine, resulting in high oil temperatures and - again - accelerated wear.

Engine-to-boiler connection

Traditional still manufacturers often choose to connect the agitator engine directly to the boiler. This is a really bad idea, specifically for copper boilers, as copper is crazy conductive. The direct connection results in direct heat transfer from the boiler to the agitator engine, severely limiting its longevity.

Here's how: the direct engine-to-boiler connection results in a massive additional heat influx into the agitator system as a whole and the agitator engine specifically. The engine oil, that is supposed to work as a lubricant, gets too hot and degrades prematurely. As its lubrication properties decline, wear & tare of the structural components in the engine and gear box set in almost immediately.

Cascading failure

Together, the aforementioned bad design decisions generate a cascading failure. In itself the agitator engine selected could do the job for some time. But as it is faced with an enormous heat influx as well as an off-set additional gear system, that is a longevity bottle-neck in itself, the engine does not stand a chance and will probably break down within two years of starting operations. As we see confirmed by distillers that use these traditional stills with their poorly designed agitator engines.

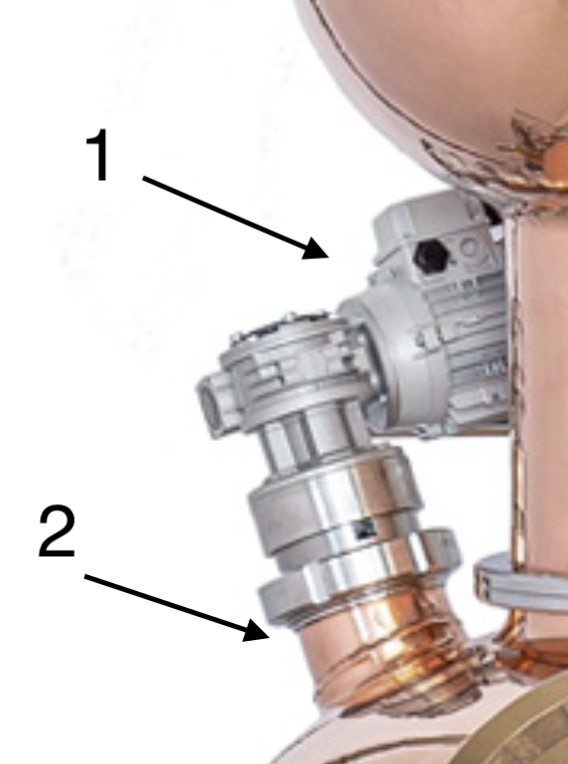

Off-set mounted (1) agitator engine that is directly connected to the boiler (2) ...

The iStill solution

How did we become the Rolls-Royce of Stills? Well, via better designed distilling systems that operate well-designed mixing systems. For example:

- The iStill agitator engine is twice as strong as needed and is therefore never stressed to the max;

- It is placed in-line with the agitator shaft for the strongest, simplest, and most direct engine-to-shaft connection;

- This also puts the agitator engine's cooling fins in line with the airflow above the still, for better cooling;

- We separate the agitator engine from the boiler with a so-called "lantern", that prevents boiler-induced heat transfer;

- Our insulated boiler prevents further indirect, hot air induced heat transfer to the agitator engine.

Summary

The devil is in the details. Or maybe we should say: "the divine is in the design"? A well-designed still consists of numerous well-designed parts that all need to work together. Only then does the still become more than the parts that it consists of. Only then does a still become more than its weakest link. And that's how you become the Rolls-Royce of Stills: by meticulously contemplating design solutions and never, ever taking a shortcut on quality.

Our agitator engine design is a great example of that. A microcosm in itself. Yes, we could have chosen a cheaper, weaker engine. Yes, we could have connected it to the boiler directly, and saved another few hundred bucks (look at the picture underneath and appreciate how big and sturdy the lantern is!). Yes, we could have gone for a single or double bearing of the whole agitator system, but we went for a triple bearing instead ... etc., etc.

All of the above iStill design choices cost money initially. But they more than make up for it via lower operating costs, less downtime, and - maybe the most important - via additional comfort for you: the comfortable feeling that you can rely on your still to do its job. Your iStill, that has a Rolls-Royce-like reputation, because it keeps your income and reputation in tact.

This is how we design and build agitators that last 10 years ...

www.iStill.com