Backroads Spirits Co.: A New Era of Distilling!

Integrating Modern Technology With a Timeless Tradition

Distilling is a proud tradition with a rich history that has been around for hundreds of years. When creating Backroads Spirits Co. we envisioned a micro-distillery where modern technology is embraced, but the tradition and heritage of distilling is not forgotten. With the use of our ultra-modern distilling equipment, we are capable of producing any type of spirit imaginable all within one still, rather than the use of multiple stills like in other distilleries. Our high-tech still through the use of intelligent artificial automation also allows us to produce top-tier products with higher consistency. This advanced technology and design also allow for our processes to be more efficient offering the capability to be up to 90% more energy efficient than traditional stills. This piece of modern distilling equipment is an extension of our vision where modern technology is integrated with a timeless tradition.

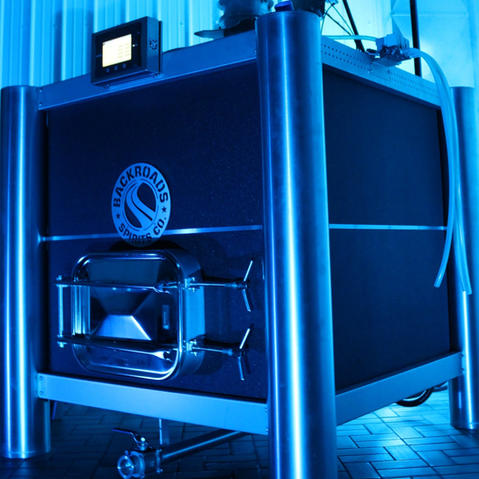

BORN FROM STEEL

Our still is made from durable, high-quality stainless steel that can outlast copper by years. The stainless steel design allows for the still to be chemically inert, not requiring the same chemicals for cleaning that copper stills may use.

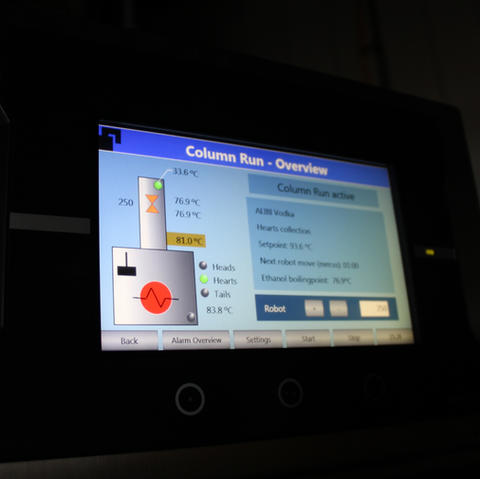

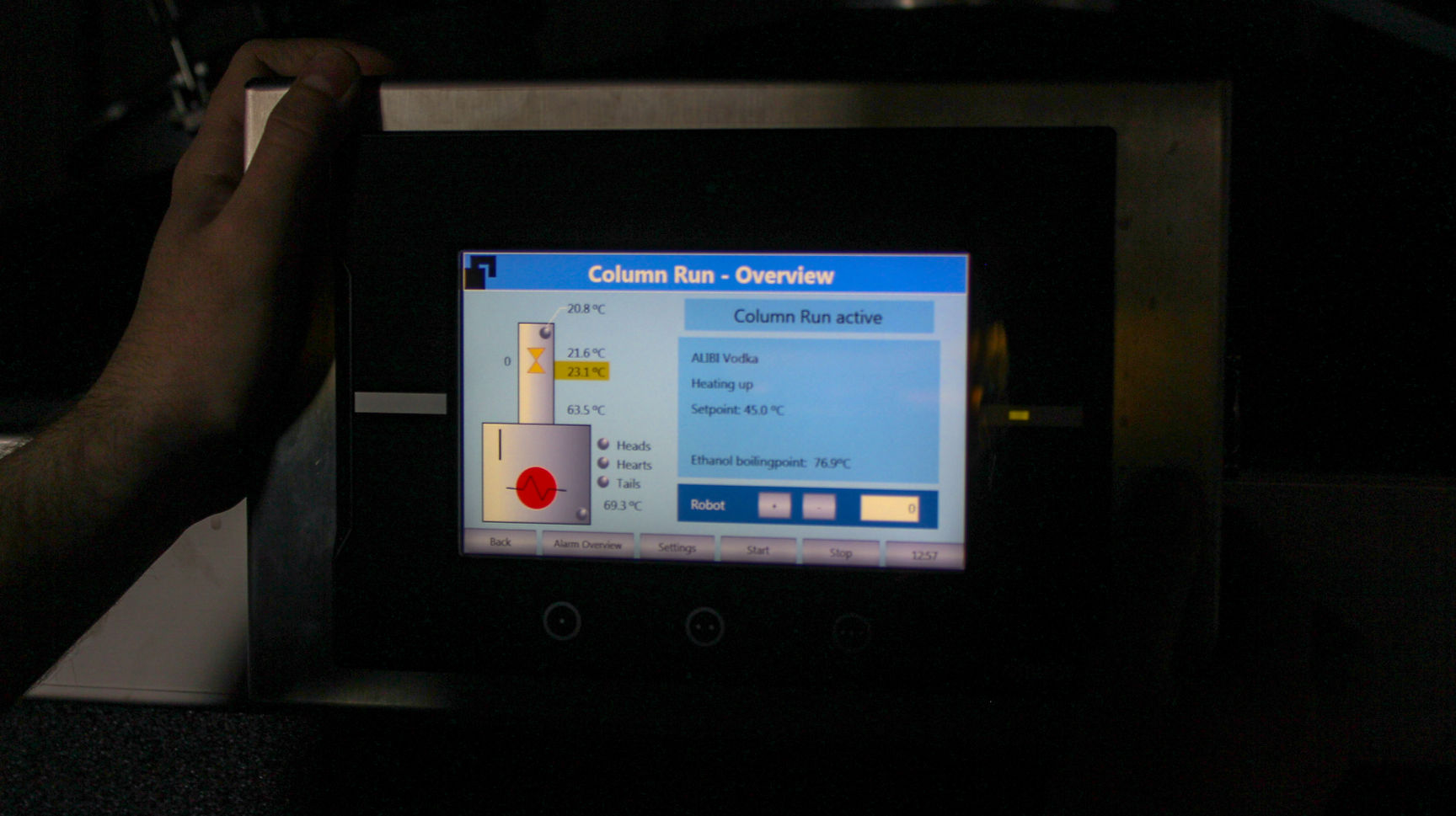

INNOVATIVE AUTOMATION

Through the use of robotization and intelligent automation our team can fully control the entire distilling process. This modern technology allows us to create consistent high-quality spirits over and over again. Our still is so smart that it measures the air pressure by the second to automatically adapt and adjust the cut points for heads, hearts, and tails. Oh, and it can even connect to our smartphones!

DIRECT HEATING

Our still is designed to use direct heating in combination with the square boiler and jet propulsion agitators to give us direct access to the Maillard Reaction. This allows us to add an additional 25% more flavour without the risk of scorching future products such as rums and whiskeys.

IT'S HIP TO BE SQUARE

Our unique square still was designed and manufactured in the Netherlands from the highest quality materials and components. The square boiler design offers a more stable distillation run where it does not create agitation of shearing. This allows our team to have more control over the selected and harvested flavour components of a run.

ENERGY EFFICIENCY AT THE FOREFRONT

The intelligent and innovative design of our still through the use of stainless steel and insualtion in a compact design allows for it to be up to 90% more energy effienent than a traditional copper still. The automated intelligence also uses the first and last bit of alcohol of each run to clean the still.

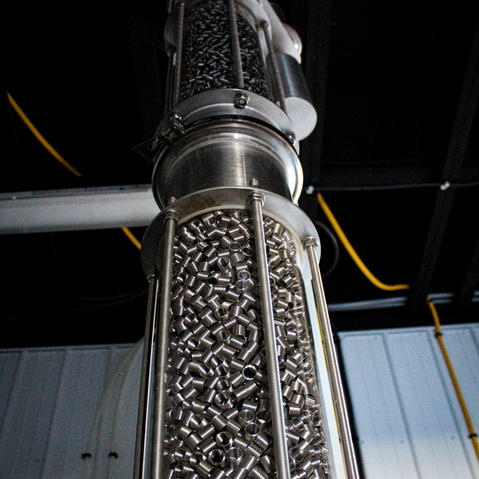

BEAUTY TO THE FINEST DETAIL

The intelligent design of our still is displayed yet again when looking at the small stainless steel springs that fill the still's column. Our still is designed to run in two modes, either column still or pot still mode, which is what allows us to produce multiple types of spirits within one still. These stainless steel packing coils create reflux when in column still mode and allow for open space when in pot still mode.

INTELLIGENT AUTOMATION AT THE TOUCH OF A HAND

Our still features a state-of-the-art LCD touch screen on the forefront of the still that allows us to read real-time data of exactly where we are with each run. As mentioned, the intelligent automation that our still features allows us to produce spirits with higher consistency to give consumers a great-tasting product every time. Also featuring Automated Cuts Management, Air Pressure Control (APC), smartphone connectivity, and many more high-tech features, our still is proudly allowing us to harmonize modern technology with a timeless tradition.

PURE H20 TRIPLE FILTERED PERFECTION

Our water is sourced directly from SaskWater before carefully undergoing an in-house triple filtration process. The water we use undergoes Carbon Filtering, Reverse Osmosis, and Ultra Violet Light filtrations to give us the purest and smoothest water possible for use in spirits production. Ensuring that our water is as pure and clean as possible is of the highest priority to us as water is an extremely vital part of spirits production.

Carbon filtering acts as a method to remove any unpleasant tastes, odors, chlorine, or any small leftover traces of sediments, dirt, and rust.

Reverse Osmosis membranes act as a method to remove any remaining traces of bacteria, viruses, or parasites in addition to fluoride, herbicides, pesticides, TDS, and any unpleasant tastes and odors that may still have been present in the water.

Ultra Violet Light water purification is then used as the most effective process for disinfecting any bacteria in the water. The UV light rays penetrate harmful pathogens in the water eliminating micro-organisms that can potentially cause illness.

https://www.backroadsspirits.ca/distilling