Copper is medicine for a bad ferment!

2 October 2019

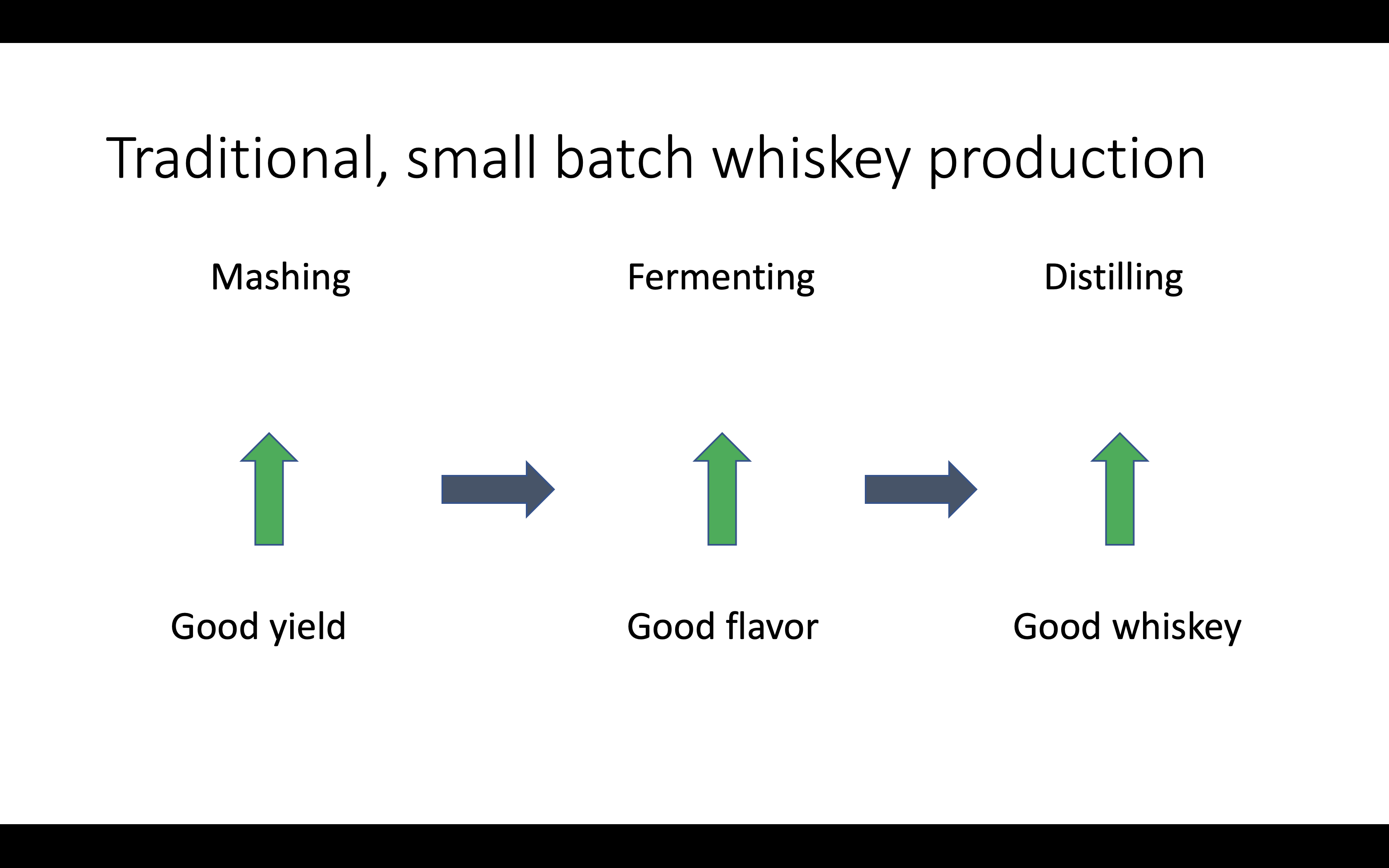

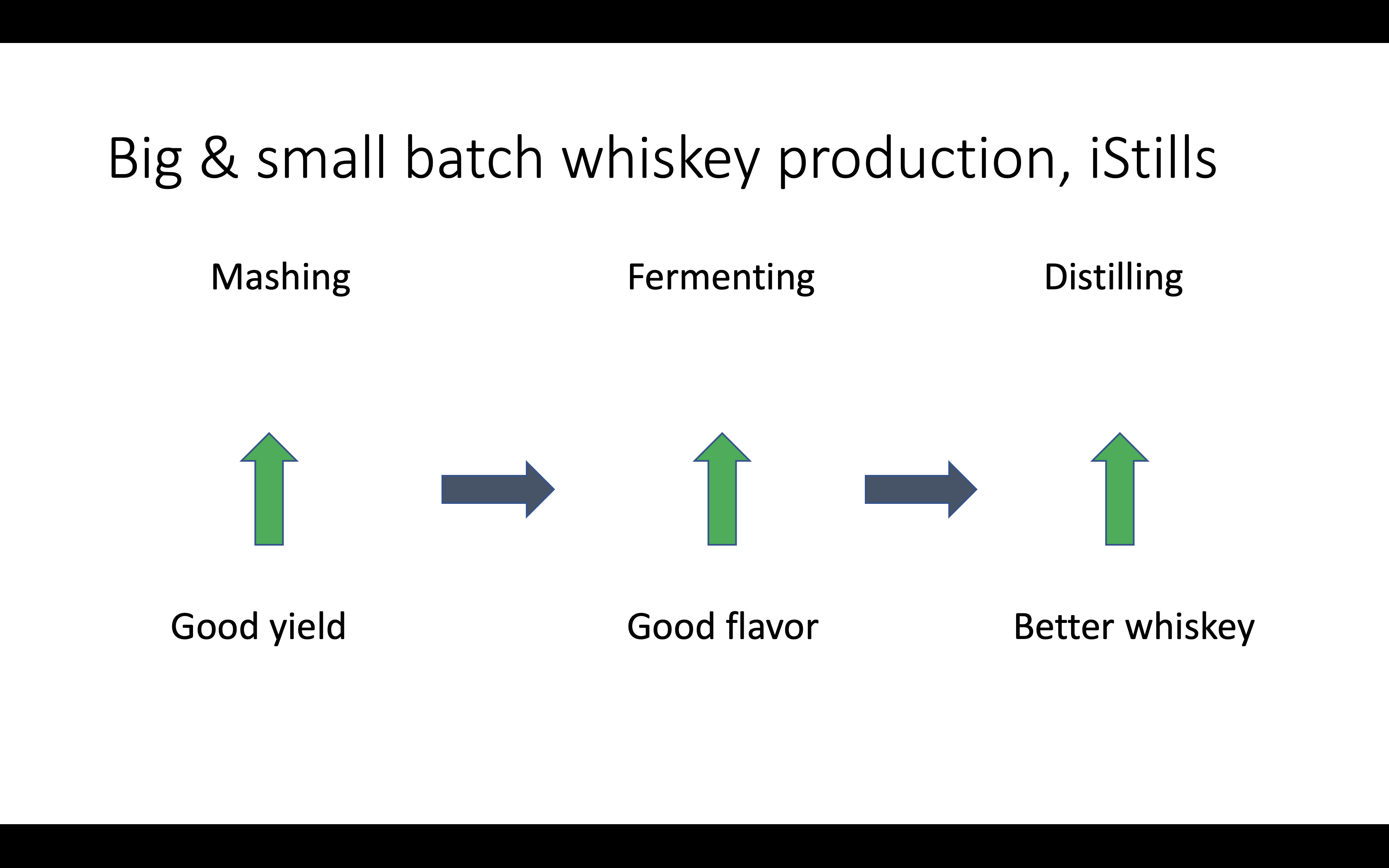

Whiskey making: the procedure

If we exclude grain handling and aging, traditionally, whiskey is made in three steps:

- Mashing (converting starches into fermentable sugars by using enzymes);

- Fermenting (converting the fermentable sugars into alcohol with yeast);

- Distilling (concentrating the alcohol and harvesting the right flavors).

Small batch traditionally allows for good control and therefore good whiskey ...

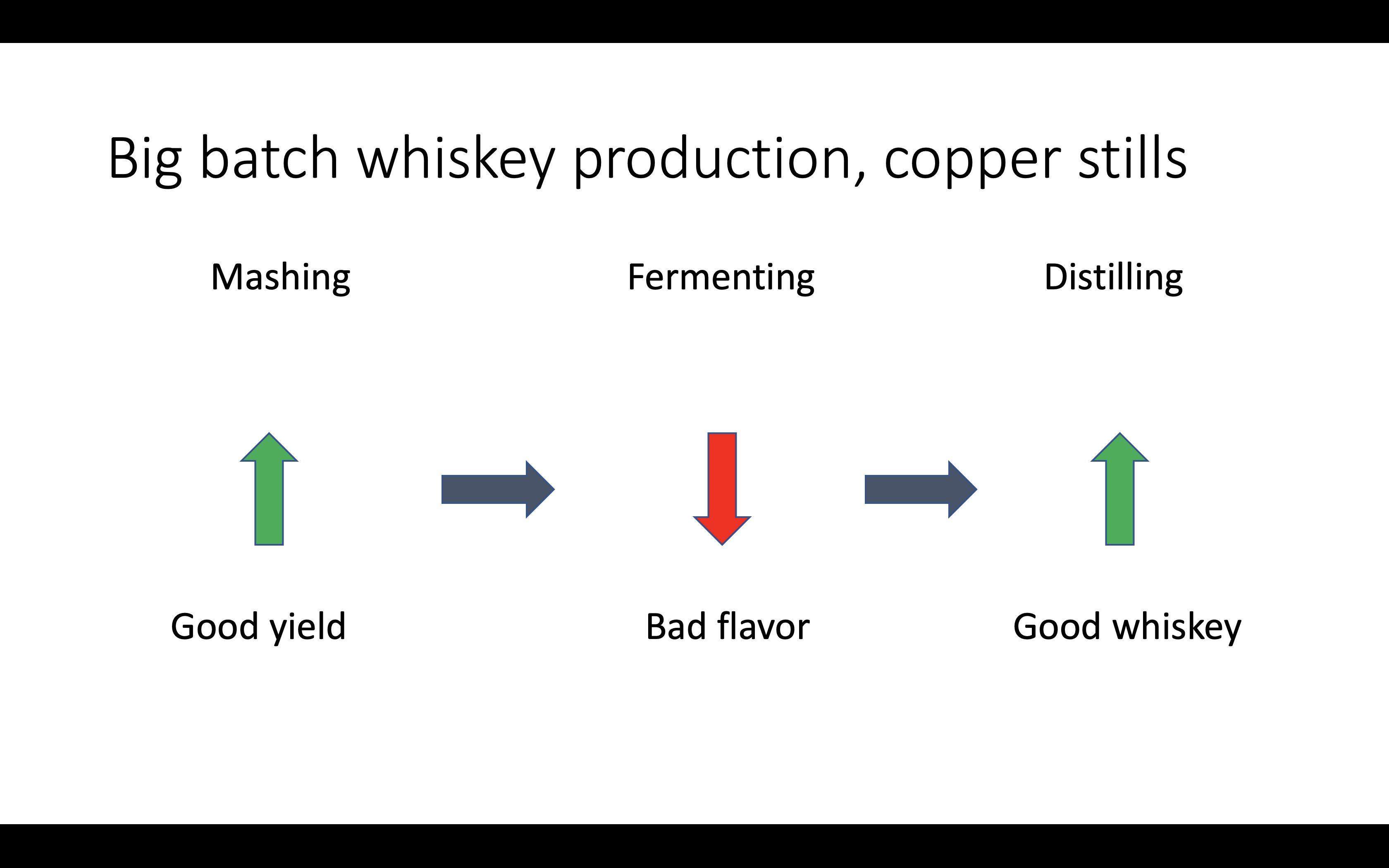

Bigger, uncontrolled ferments generate bad flavors that copper catalyses ...

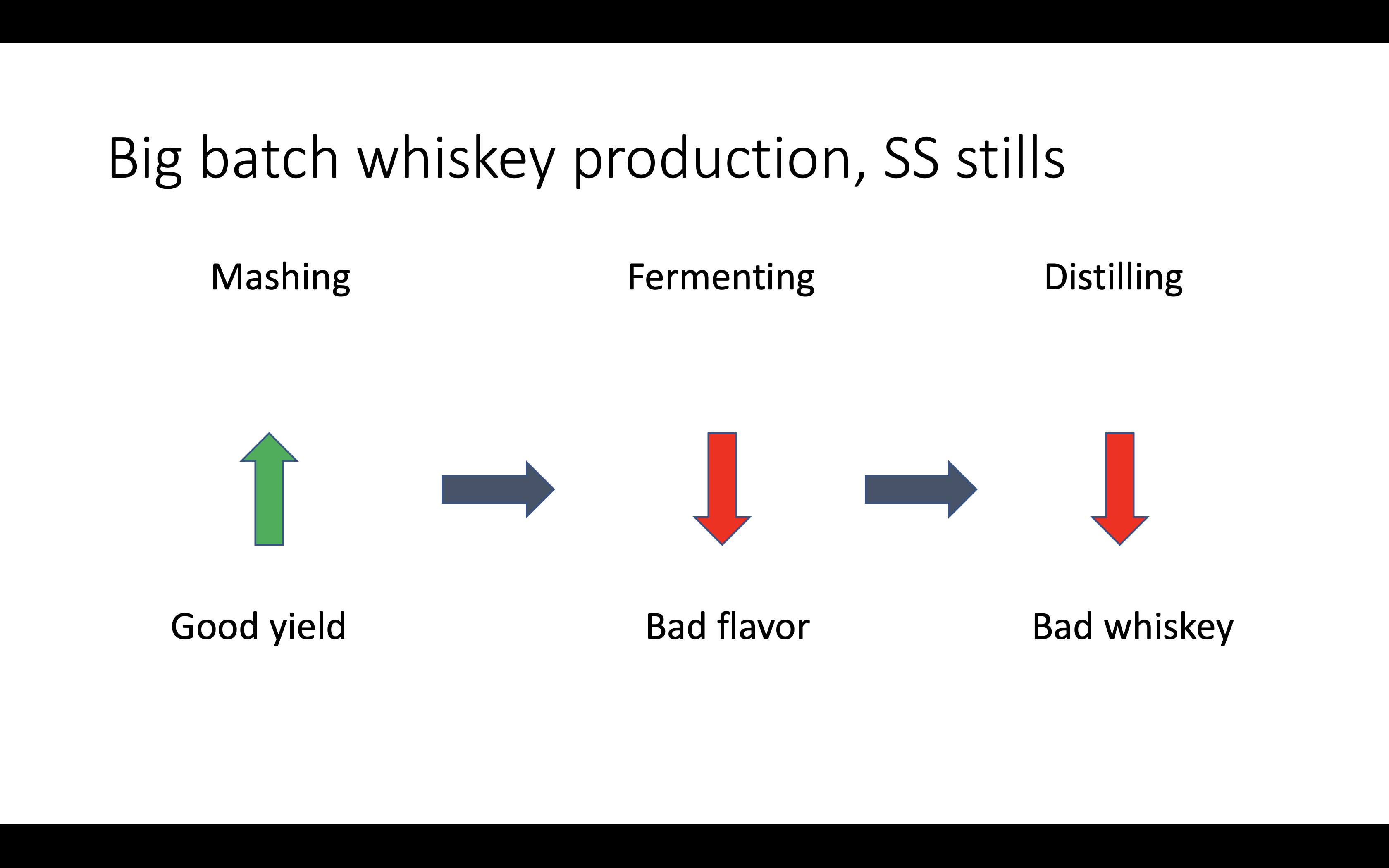

With SS stills, sulfurs no longer got catalyzed, and bad ferments got exposed ...

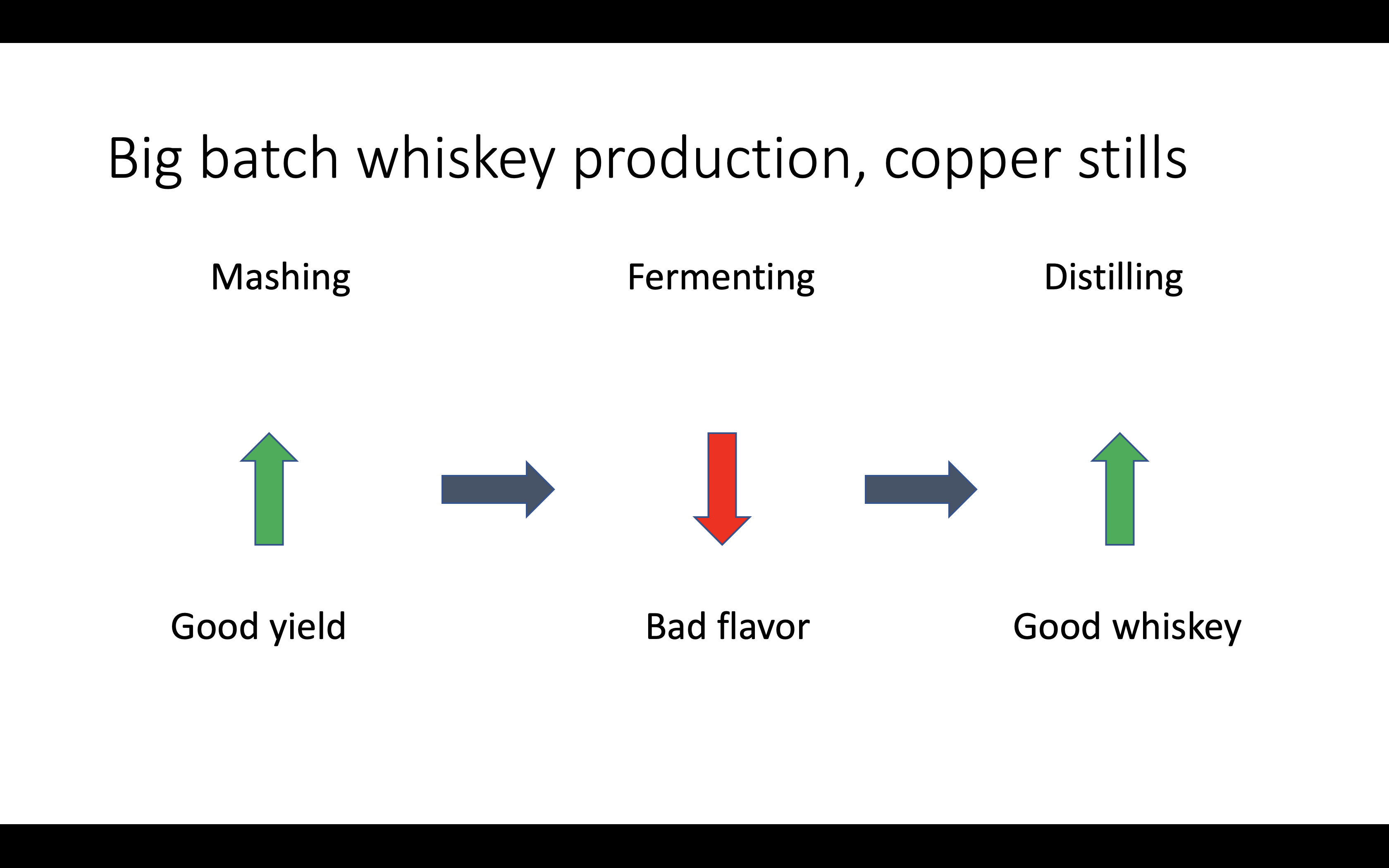

So the distilling industry switched back to copper stills ...

- Uncontrolled, overheating fermentations create more bad flavors than just sulfur;

- The copper clean-up during distillation does not polish-up all of those;

- Copper stills oxidize, creating copper contaminated whiskey;

- Copper stills need extensive cleaning, making for longer working days;

- Due to oxidation and cleaning, copper stills need to be replaced in 10 to 15 years.

- Mash in a controlled environment, to achieve maximum yield;

- Ferment in a controlled way, to achieve maximum flavor;

- Distill in a controlled way, to achieve maximum yield and flavor.

iStill gives you the control to make better whiskies ...

iStill copper waffles: well-used ...

www.iStill.com