Neutralizing Air Pressure Variation!

5 April 2019

Introduction

If you, as a craft distiller, want to make the best spirits possible, you need to have full control over all variables. If you want to make the beste spirits consistently, you need even more control. This iStill Blog post dives into the influence of air pressure, how it can screw up your run, and how iStill's innovations help solve the issue.

The influence of air pressure on distilling

When distilling spirits, we aim to first concentrate the alcohol by a fast stripping run. Thereafter, a slower finishing run is performed where the heads, hearts and tails fractions are separated by means of boiling point differences between those fractions. Heads come over at lower temperatures than hearts and hearts boil off at lower temperatures than tails.

From the above alinea it becomes clear that boiling points are key to good cuts management. Just as good cuts management is essential to bring over the right flavors and create that above top shelf spirit you are after.

So good cuts management, essential to the creation of great spirits, depends on boiling points. And guess what? Boiling points depend on air pressure! And since air pressure is not a given, not a set parameter, it creates variability in your cuts, translating into potentially sub-standard quality drinks.

Air pressure structurally differs between locations. As a general rule: the higher altitude your location is, the less air sits above your still, the lower the air pressure is. Air pressure is also variable in time. When a new weather front moves in, air pressure will rise or lower. The issue with this? As a distiller you are constantly confronted with different air pressures, translating to different boiling points. Between runs and during runs.

Ethanol, for example, boils at 78.3C or 173F. At standardized sea level air pressure that is. Higher air pressure pushes boiling points upwards by up to 0.5 degrees easily. Lower air pressure lowers ethanol's (and other components) boiling point.

Air pressure sensor old style ...

- Heads are collected until 80C;

- Hearts are collected until 95C;

- Tails are collected until 98C.

Due to air pressure variance, you just screwed up your finishing run ...

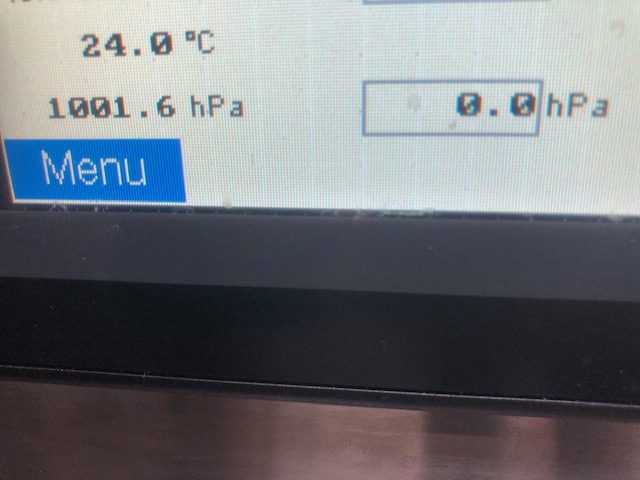

Air pressure sensor iStill style ...

www.iStill.com