Innovation: New iStill 5000!

4 January 2019

Introduction

iStill is all about introducing new technology that will make your life as a craft distiller easier. "Distilling made easy" is not just our tagline, it is the compass by which we navigate. And today we are proud to introduce the all new iStill 5000. Distilling made easier, bigger, and faster ...

In this Blog post let's first look at what distillation is al about. Then, as a next step, we can draw up specifications on what constitutes a well-designed still. Last, let's take a closer look at what the all new iStill 5000 has to offer.

The iStill coffee mug on top of the iStill 5000 cooler and CIP ...

Odin in front of the iStill 5000 ...

Assembling the iStill 5000 column ...

Distillation as an alcohol and flavor selection process

Not all alcohols are created equal. Some alcohols, like acetones, boil at very low temperatures. Others, like furfural, boil at very high temperatures. Just as with alcohol in general, which has a lower boiling temperature than water, it's the light alcohols that come over during the first part of the distillation run, while the heavier ones come over during the later part of the run (when the low and medium boiling point alcohols are depleted). This distinction between factions is very important and is also referred to as Heads (lower boiling point infected alcohol), Hearts (the good stuff), and Tails (high boiling point infected alcohol). During distillation we want to cut out Heads and Tails, while keeping the Hearts. The reason for that? Lower and higher boiling point alcohols like acetone and furfural are not healthy. Cutting them out results in a healthier end result. Now, let's continue with the flavor selection part of distillation. Basically, we can group the flavors in three factions:- Base substrate flavors (e.g. grainy flavors in whiskey, molasse flavors in rum);

- Fruity flavors;

- Root-like and nutty flavors.

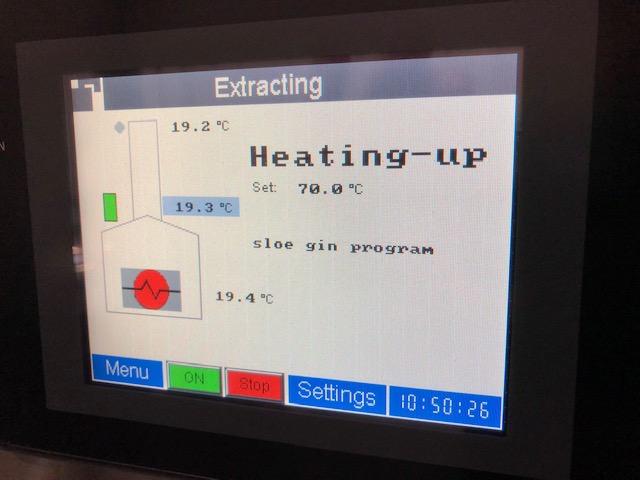

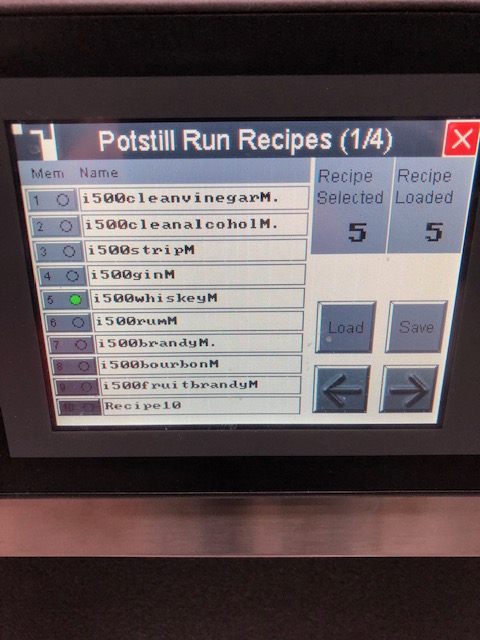

The iStill 5000 is fully automated ...

- Versatility;

- Flavor;

- Control;

- Ease of use;

- Efficiency;

- Longevity.

iStill Whisky Distillery ...

- Most stills out there score low on versatility. In general, pot stills are either strippers or finishers but seldom both. A one-distillation-approach is theoretically possible with a plated still, but comes at a cost: root-like and nutty end of run flavors hardly come over, creating a less interesting, 2-dimensional rum or whisky;

- Most stills are indirectly fired (via a steam boiler and/or jacket), meaning they don't give you the Maillard Reaction. Some stills (especially the smaller ones) have direct submersible heaters. They could help create the Maillard Reaction, but cannot distill on the grain or pulp, limiting flavor gains;

- Existing still technology, at a craft distilling level, offers only manual control. This results in the distiller's subjective taste deciding on flavor composition. Optimized cuts and repeatable spirits production become impossible to realize;

- Ease of use is essential for day-to-day operations as well as brand development. The craft distiller needs to be out there telling his story and selling his drinks. If he (or she) is locked-up behind the still, those two essential roles cannot be fulfilled. And remember: making drinks costs money. It's selling drinks that keeps the lights on! Unfortunately, since manual control is the standard, most (if not all) stills need constant supervision and human control, taking the distiller out of the branding and marketing operation;

- Efficiency. Most units are not insulated, use non-integrated heating systems, and are not designed to optimize for energy consumption;

- Longevity. Our research shows that most stills are designed to last. The exceptions are some Chinese and Central/Eastern European still builders. The complaints we heard about some Chinese manufacture, is that it can be made from lower quality stainless steel or that coolers do not work efficiently enough. We haven't witnessed this ourselves though. The complaints towards a specific Central European still builder is that sheeting is too thin, that they use (corrosive!) iron instead of (promised) stainless steel, and that electronics and agitators fail. Unfortunately, we have proof (pictures and customer testimonials) that these complaints are real.

Cheap Polish still breaks down on its maiden run ...

Our digital master distiller is at your service via the iStill Spirits Library ...

- 5,000 liter net capacity;

- Insulated flush square boiler design;

- Newly designed 12 inch diameter column;

- Gin hooks;

- Weight: 1350 kilo;

- Sizes: 250x255x450/600 (wide, deep, high, in centimeters, potstill/column);

- Power: 90 kW;

- Stripping, gin distilling: 200 liters per hour at 30%;

- Finishing brandy, rum, and whisky: 120 liters per hour at 60%;

- Finishing vodka: 75 liters per hour at 95%;

- Run time: 8 - 12 hours (stripping, finishing taste rich, finishing vodka);

- iStill Boiler Radiator for direct (instead of indirect) cooling;

- Manholes: 40/60 cm diameter, one at top, one near bottom;

- Supports on the grain, potato or pulp distillation;

- Patented indirect heater system;

- PLC system and touch screen computer, with:

- Automated distillation programs;

- Cuts, time, temperature, agitator, power management and air pressure control;

- Internet connectivity, smartphone & computer management and control;

- Optional: WiFi, pot still column, glass column sections, extractor, etc.

iStill 5000: the complete package ...

Assembling the iStill 5000 ...

https://www.istill.com/designstudio/i5000