iStill NextGen 500 ... on Gas!

20 May 2016

Introduction

One of our customers from the Netherlands, Stokerij Texel, makes gin and vodka. The vodka is made from potatoes. They already have the iStill 250 Base Series for the gin and vodka making processes, but how about stripping that thick potatoe vodka wash?

Considerations

Their prime concerns were the thickness of the potatoe wash and its ability to "store" CO2. The thickness made CO2 release difficult. And when you put a thick CO2 rich wash in a still, and bring it to a boil, it tends to puke. Puking thick potatoe wash into the iStill 250's column, wasn't ideal, since it meant they needed to clean out the column and its packing too often.

Stokerij Texel turned to iStill for a solution, and since we were close to releasing the new NextGen line-up, we proposed them to tailor a NextGen unit to their needs. Like this:

- NextGen 500 liter flush square boiler design;

- Jet Propulsion Agitator System;

- Direct Gas Fired Heating System;

- Stripper column.

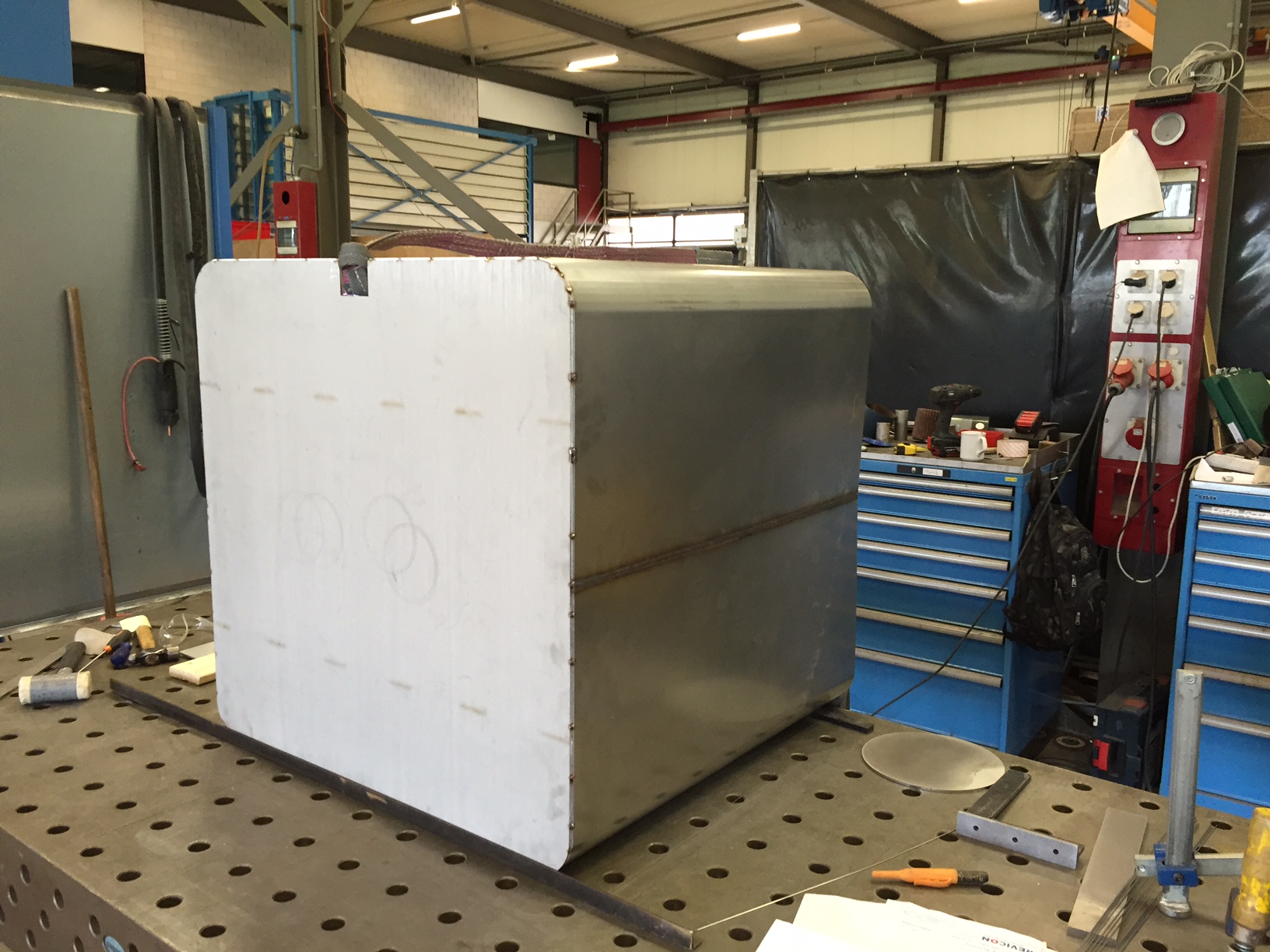

Welding the gas fired 500 liter boiler ...

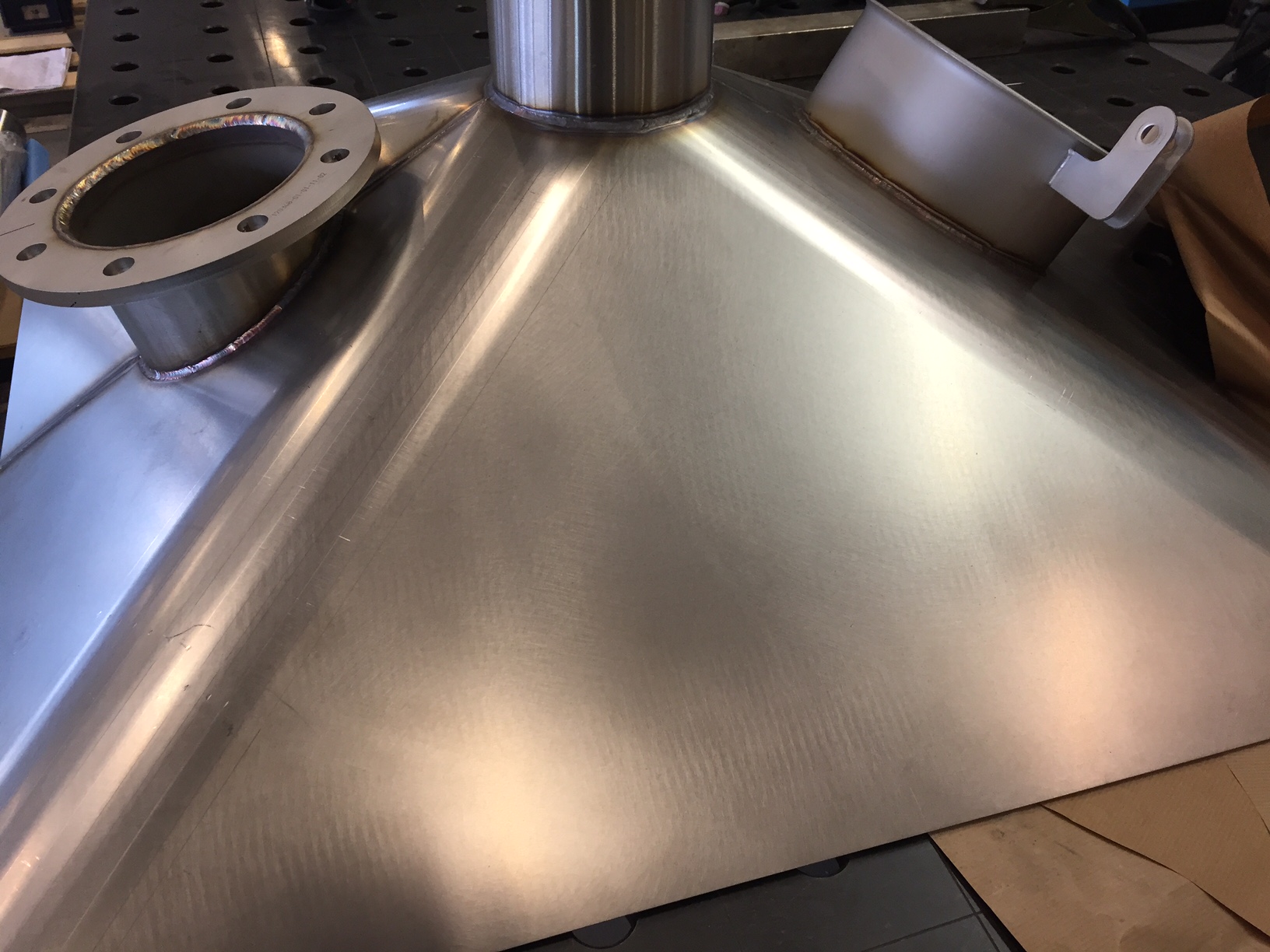

Boiler roof with agitator flange (l) and manhole (r) ...

The boiler nears completion ...

All dressed up, with insulation and variable skirts ...

Additional manhole at the back ...

Erik enters JPAS ...

Now isn't she a pretty thing ...?

Building the stripper column ...

[gallery ids="3807,3808" type="rectangular"]www.iStill.eu