On boiler design, agitation and taste!

7 May 2016

Introduction

This is both a theoretical and a practical post. Theoretical, because I will dive in deeper on how a boiler should be designed to work optimally. Practical, because I have put the theory to the test by actually designing and building, according to those principles, the non plus ultra boiler for the new iStill 500 NextGen.

Boiler design and taste

The role a boiler plays in any distilling device, when maximizing taste is the goal, is twofold:

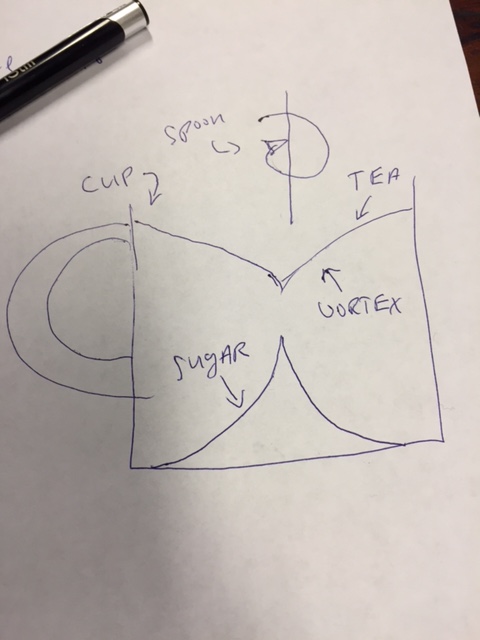

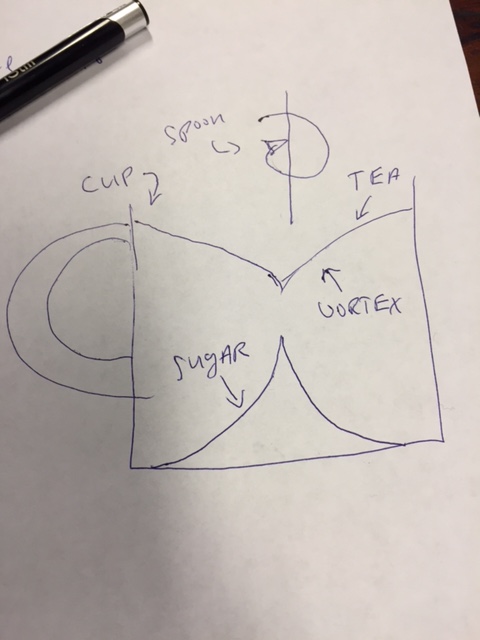

Stirring at high rpm in a round glass or boiler creates a vortex and centralizes particles. A vortex is bad, because it disturbes the gas bed above the liquid and because it severely limits the maximum filling charge a boiler can take. Particle centralization (instead of perfect particle distribution) potentially creates burn issues.

The NextGen boiler design

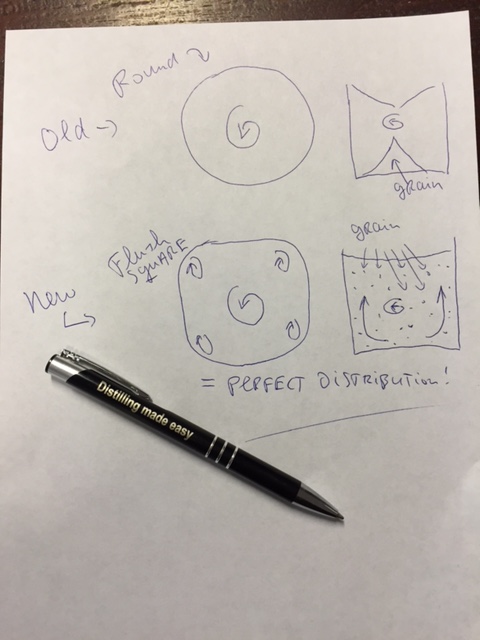

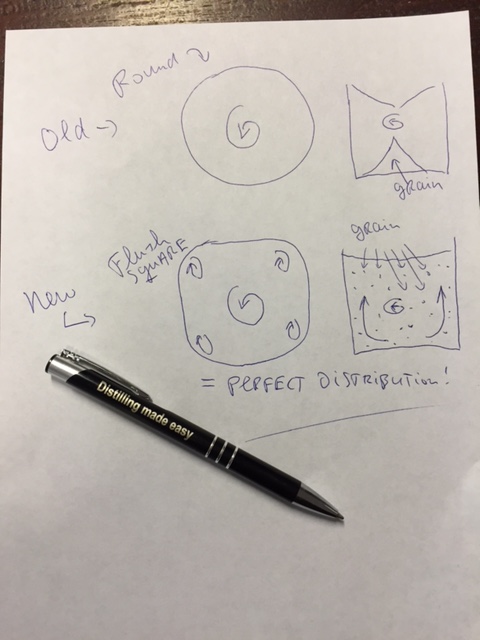

I wanted the NextGen boiler to solve my teacup paradox, and this is what I did: I created a flush square (and patented!) design. The flush part helps circulation, where 90 degree angles would have hampered it. And the square design actually breaks up the vortex. And more! The four corners of the flush square boiler design act as "chimneys", sucking up grains from the bottom and redistributing them to the top.

Instead of a vortex, with centralized particles, the new boiler design and agitator create a stable liquid bath with perfect particle distribution!

Like this:

Stirring at high rpm in a round glass or boiler creates a vortex and centralizes particles. A vortex is bad, because it disturbes the gas bed above the liquid and because it severely limits the maximum filling charge a boiler can take. Particle centralization (instead of perfect particle distribution) potentially creates burn issues.

The NextGen boiler design

I wanted the NextGen boiler to solve my teacup paradox, and this is what I did: I created a flush square (and patented!) design. The flush part helps circulation, where 90 degree angles would have hampered it. And the square design actually breaks up the vortex. And more! The four corners of the flush square boiler design act as "chimneys", sucking up grains from the bottom and redistributing them to the top.

Instead of a vortex, with centralized particles, the new boiler design and agitator create a stable liquid bath with perfect particle distribution!

Like this:

Movie ...

As the proof of the pudding is in eating, the proof of perfect boiler design and agitation is in seeing it happen before your own eyes ... so here's a short movie. It will show you how the new boiler design and agitator work together to prevent vortex formation and particle centralization. If you look at the four corners of the boiler, you can even see the chimney effect:

https://www.youtube.com/watch?v=X_nw7oVDk_M

Movie ...

As the proof of the pudding is in eating, the proof of perfect boiler design and agitation is in seeing it happen before your own eyes ... so here's a short movie. It will show you how the new boiler design and agitator work together to prevent vortex formation and particle centralization. If you look at the four corners of the boiler, you can even see the chimney effect:

https://www.youtube.com/watch?v=X_nw7oVDk_M

- Does the boiler enhance the formation of taste molecules (esters) during distillation?

- Does the boiler provide these taste molecules to the column in such a way that they can be harvested easily?

- A vortex was created, pushing the liquid down in the center while pushing it up near the edges of the glass;

- The sugar gathered in the center of the glass and did not disperse evenly at all.

Stirring at high rpm in a round glass or boiler creates a vortex and centralizes particles. A vortex is bad, because it disturbes the gas bed above the liquid and because it severely limits the maximum filling charge a boiler can take. Particle centralization (instead of perfect particle distribution) potentially creates burn issues.

The NextGen boiler design

I wanted the NextGen boiler to solve my teacup paradox, and this is what I did: I created a flush square (and patented!) design. The flush part helps circulation, where 90 degree angles would have hampered it. And the square design actually breaks up the vortex. And more! The four corners of the flush square boiler design act as "chimneys", sucking up grains from the bottom and redistributing them to the top.

Instead of a vortex, with centralized particles, the new boiler design and agitator create a stable liquid bath with perfect particle distribution!

Like this:

Stirring at high rpm in a round glass or boiler creates a vortex and centralizes particles. A vortex is bad, because it disturbes the gas bed above the liquid and because it severely limits the maximum filling charge a boiler can take. Particle centralization (instead of perfect particle distribution) potentially creates burn issues.

The NextGen boiler design

I wanted the NextGen boiler to solve my teacup paradox, and this is what I did: I created a flush square (and patented!) design. The flush part helps circulation, where 90 degree angles would have hampered it. And the square design actually breaks up the vortex. And more! The four corners of the flush square boiler design act as "chimneys", sucking up grains from the bottom and redistributing them to the top.

Instead of a vortex, with centralized particles, the new boiler design and agitator create a stable liquid bath with perfect particle distribution!

Like this:

Movie ...

As the proof of the pudding is in eating, the proof of perfect boiler design and agitation is in seeing it happen before your own eyes ... so here's a short movie. It will show you how the new boiler design and agitator work together to prevent vortex formation and particle centralization. If you look at the four corners of the boiler, you can even see the chimney effect:

https://www.youtube.com/watch?v=X_nw7oVDk_M

Movie ...

As the proof of the pudding is in eating, the proof of perfect boiler design and agitation is in seeing it happen before your own eyes ... so here's a short movie. It will show you how the new boiler design and agitator work together to prevent vortex formation and particle centralization. If you look at the four corners of the boiler, you can even see the chimney effect:

https://www.youtube.com/watch?v=X_nw7oVDk_M

www.iStill.eu